Smartphone owners often have to face this statement ‘your phone needs micro-soldering'. Not knowing what this is all about a lot of users simply opt out of the process assuming that it’s some expensive job which is likely to cost a huge sum of money. Here we are going to explain what micro-soldering really is.

What is soldering?

Soldering is an intricate job involving the connection of wires by means of a metal alloy made from tin and copper. The metal alloy is used to connect metal surfaces. Furthermore the alloy has a melting point of 850 degrees Fahrenheit. The main purpose of soldering is to allow the surface joined by wires to become electrically conductive. Alloys allow electricity to flow around a metal surface.

Why do phones need micro soldering?

Often times the motherboard of a smartphone gets damaged prompting the user to seek phone repairs in Brunswick. When it comes to joining two components micro soldering comes to the rescue. This intricate job of handling tiny components on a phone demands skills and knowledge. Typically its role becomes prominent when a wire or component needs to get fused into the circuit after a considerable damage. There are different types of solders available. The difference lies with their component and purpose. The solders can be either leaded or non-leaded. It’s a fact leaded solder has lower melting point than non-leaded solders. At times mobile phone repairs experts in Reservoir will use bismuth to develop lower melting point.

Use of flux in soldering

During micro soldering flux is widely used. Flux is basically a thick liquid which lets the solder to flow into a specific connection where the repairing expert wants it to melt. It is a fact without the use of flux soldering doesn’t take place properly. Absence of flux makes dry connection.

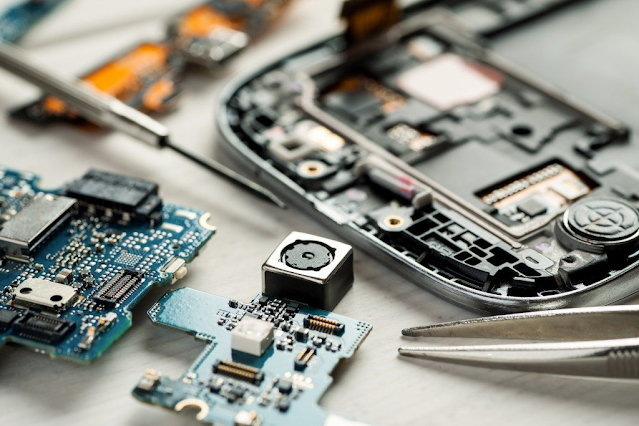

Microsoldering is often applied on small sized smartphones. Under certain scenarios microsoldering becomes integral especially when surface components need to be shrunk. Suppose you are the owner of a Samsung phone which has undergone screen damage you will need Samsung screen repair in Reservoir which might prompt the expert to dismantle the phone and its micro components which can only be treated with microsoldering. Standard tools will hardly be of use to the expert. The size of the components are so tiny that they can be smaller in size than a rice grain.

Sometimes when the components get even smaller the expert will need a tinier soldering tip. Also under such scenarios the use of a microscope becomes necessary. Hence the term microsoldering becomes more apt. When anything needs to be repaired or soldered with the help of a microscope the process is called microsoldering.

No comments:

Post a Comment